BINDING AND STITCHING

If you are not experienced in preparing this type of artwork for commercial printing, we recommend enlisting the skills of our graphic design team via the form on the website.

Perfect Binding

Perfect binding is a form of booklet making in which all pages are bound along the spine using special adhesive. Perfect binding is suited to larger books from 48 pages to over 300 pages.

Requirements when creating artwork for perfect bound books:

- The internal pages must be be supplied as a 1-Up multiple page PDF file.

- Due to adhesion requirements, on the first page and last page, the first 5mm next to the spine (a narrow strip) must be kept free of all artwork.

- All text pages must contain 3mm of internal and external bleed. To ensure text or important graphics are not obscured by the spine/binding, we recommend all such elements be placed no closer than 20mm (10mm at an absolute minimum) to the binding edge.

- Make sure that artwork is supplied at the correct page size.

- Ensure that your artwork has the correct number of pages.

- Due to the nature of perfect binding, we do not recommend text elements are placed across page spreads. Elements which are are placed across page spreads may not line up exactly in your finished book.

Plastic Comb Binding

Binding a stack of paper together by inserting the teeth of a flexible plastic comb into holes punched along one of the edges.

Spiral Binding

A type of binding where a metal or plastic wire is spiralled through holes drilled along the binding side of a document.

Wire Binding

Binding a stack of paper together by inserting punched onto a “C” shaped spine that is then closed by squeezing the spine together until it is round. Documents that are bound with wire binding will open completely flat on a desk and allow for 360 degree rotation of bound pages.

Saddle Stitching

Saddle stitching is a form of binding in which all pages are folded and bound in the centre of the booklet from the outside using staples. Saddle stitching is suited for booklets or magazines with 8 pages to 80 pages.

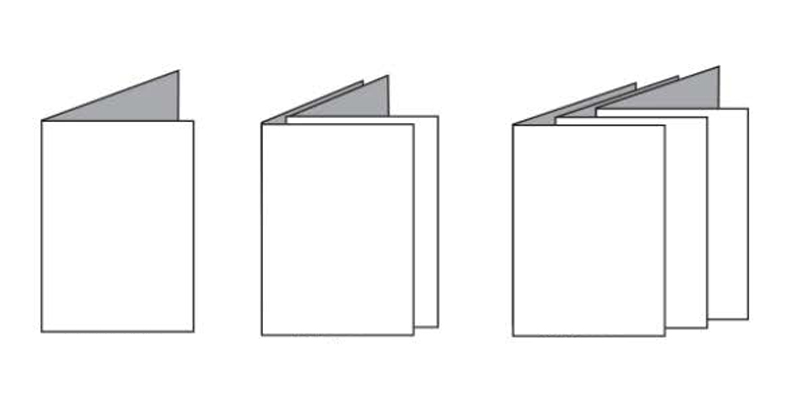

Why do books that are saddle stitched go in multiples of 4 pages?

Many booklets are created with the saddle stitch binding method. This economical method uses printed sheets that are folded and nested one inside the other and then stapled through the fold line with wire staples. The staples pass through the folded crease from the outside and are clinched between the centre pages.

Since each folded sheet nested within the finished booklet will form 4 pages of the booklet, it is only possible to create booklets with 4 pages, 8 pages, 12 pages, 16 pages, 20 pages, 24 pages, 28 pages, 32 pages and so on. Any combination is allowed as long as it is a multiple of 4 and we recommend not to exceed 80 pages (in this case we recommend perfect binding).

Note: Even if a page within the booklet is blank, it still counts as a page.

PP (Printed Pages)

PP (Printed Pages)

PP stands for “printed pages.” As the paper is folded in half for saddle stitching, one sheet creates 4 pages. For example: A 16pp A4 Magazine = 4 x A3 sheets, double sided, folded and saddle stitched to A4.

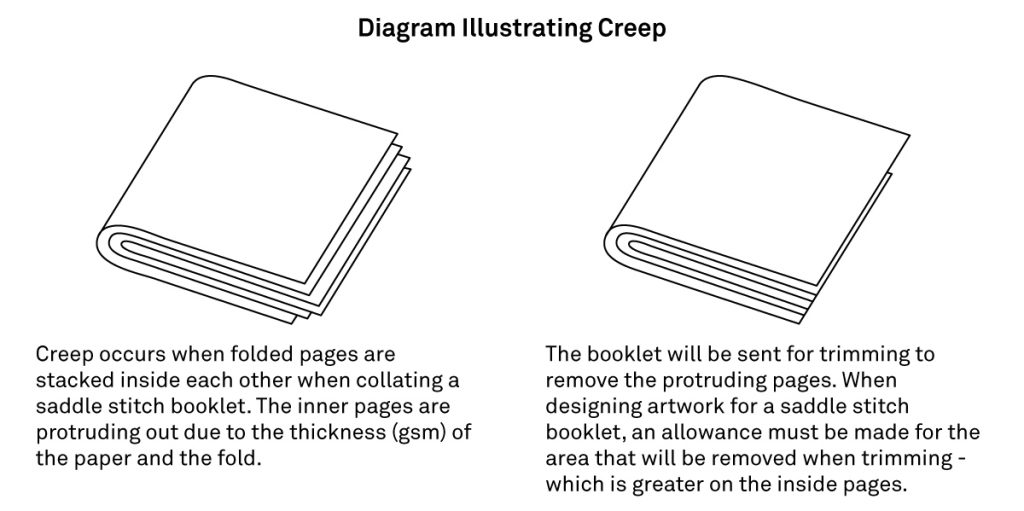

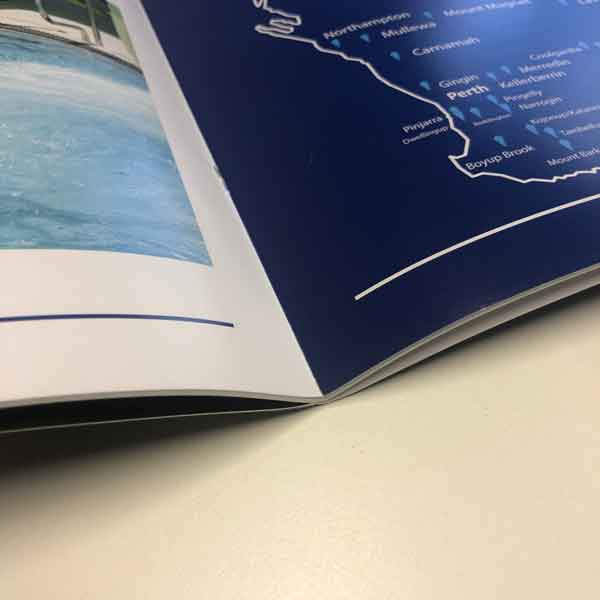

Creep

Also known as shingling, creep describes the effect where the cumulative thickness of a saddle stitched booklet/magazine causes the edges of the inner pages to gradually protrude beyond the edges of the outer ones. The greater the number of pages, the greater the effect of creep. Creep results in the margins of the inner pages becoming progressively smaller and smaller.

Due to creep, a minimum of 5mm internal bleed is required for ALL saddle stitched booklets and magazines.

Booklet Notching

Due to the saddle stitching binding method, small notches on the bottom or top edge of the spine can occur during trimming.

If they do occur, notches are usually very small and not very noticeable. However you can prevent them from occurring by ordering laminate on the cover at the time of placing your order.

Saddle Stitching

Perfect Binding